When large or variable-sized parts were involved, set up time became heightened, which could lead to costly downtime and inefficiencies.

However, fiber laser marking technology has advanced and its required footprint has contracted. Now it has become possible to bring a portable fiber laser marking unit directly to your parts instead of the other way around, saving both time and money.

Before delving into this new portability advancement, the first question is whether fiber laser marking technology is the best fit for your marking needs (rather than dot peen, scribe, or other marking processes). Fiber lasers deliver numerous advantages in marking. So, when is fiber laser marking the right alternative?

In general, fiber laser marking is a robust, reliable, and repeatable permanent engraving option. First-generation technologies, such as lamp lasers and diode-pumped lasers, have been replaced by highly efficient fiber lasers needing far less power consumption. The fiber source structure generates an extremely precise light propagation. This results in a small, well-defined laser beam in which energy concentrates mostly in a center point without power dispersion, allowing for high-definition marks on even the smallest workpieces. The high-power density of the laser beam also supports faster marking speeds than older laser technologies.

Fiber lasers are air-cooled, requiring little to no maintenance, such as lamp or filter replacement that was commonly required in older, water-cooled laser systems. Moreover, the fiber laser source is rated for a lifetime that can approach 100,000 hours. There is also minimal setup time as fiber lasers don’t require ongoing alignment or adjustment of optics. Fiber lasers are essentially “plug-and-play” machines with only three key setting parameters (power, velocity, and frequency) required.

Fiber lasers are air-cooled, requiring little to no maintenance, such as lamp or filter replacement that was commonly required in older, water-cooled laser systems. Moreover, the fiber laser source is rated for a lifetime that can approach 100,000 hours. There is also minimal setup time as fiber lasers don’t require ongoing alignment or adjustment of optics. Fiber lasers are essentially “plug-and-play” machines with only three key setting parameters (power, velocity, and frequency) required.

Fiber lasers mark rapidly on a wide range of metals, including steel, aluminum, copper, and more. Their wavelength, which is smaller than a CO2 laser but larger than UV lasers, supports marking on most industrial materials. Some materials (e.g., certain resins, wood, and glass), however, that require CO2 laser marking technology for optimal results.

Fiber lasers can create intricate and detailed marks, including logos, images, and barcodes, along with more standard alphanumeric characters common in serialization. The marks typically are highly visible once settings are optimized for the compatible base material.

Along with the marking content and appearance, the decision between fiber laser versus other marking processes (e.g., dot peen and scribe marking) often comes down to the desired marking depth. The surface-level mark created by a fiber laser typically doesn’t puncture the base material like dot peen and scribe markers do—a feature that may be a requirement in industries such as food and aerospace, where material indentations are sometimes restricted. With more power and several passes over the same area, however, fiber lasers can be used to penetrate the surface, if so desired. Furthermore, for steel treatments like galvanizing and powder coating, fiber laser marks typically are only used to mark after the steel treatment occurs, whereas dot peen and scribe can create a deep, permanent mark that may survive the treatment process.

Is Portability Needed?

Once you’ve determined that fiber laser marking is the right fit, the next question is how to deploy it most efficiently. A lot can be done with a portable fiber laser machine free from stationary setup constraints.

Which parts need to be marked? How many? What are their dimensions? If the application requires repetitive marking of a large volume of small parts, then a stationary fiber laser may be a suitable option. In addition, if automation is desired, a stationary machine again is worth considering. But if several parts are scattered throughout your plant; if the parts are large, difficult, or inefficient to move; or if your production processes could benefit from marking on the go or at various sites in the field, then a portable fiber laser marker may be the right choice.

Key Portable Fiber Laser Marking Features

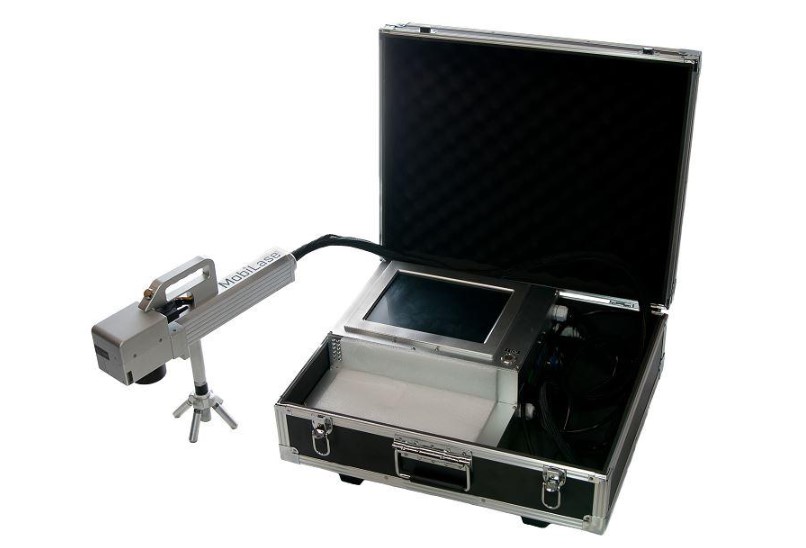

A portable fiber laser marker should include several key features to achieve optimal marking results. First, the package should be an all-in-one, lightweight unit that can be carried easily or rolled around a facility.

In addition, the laser source wattage should be sufficient to produce an industrial-strength mark at a fast speed, typically at least 20 to 30 W.

From a hardware standpoint, the unit should have a case that contains the laser source, an integrated PC, and a lightweight, hand-held applicator that is tethered to the laser source through an industrial cable. The applicator’s structure will enable easy marking consistently from the same distance, thus ensuring proper alignment and focus. The applicator will also have one or more bracket options that affix to it for positioning and marking from various angles. These brackets further support repeatable, rapid marking from the same focal length.

The unit’s PC should be embedded and come equipped with software capable of rapidly programming various marks on the unit itself and transferring via a USB interface. The software package also should include preloaded settings such as speed, power, and focal distance for marking different materials. This will support the rapid transition from marking on one material type to another.

The unit’s PC should be embedded and come equipped with software capable of rapidly programming various marks on the unit itself and transferring via a USB interface. The software package also should include preloaded settings such as speed, power, and focal distance for marking different materials. This will support the rapid transition from marking on one material type to another.

A laser pointer is an important feature for proper positioning and for simulating the mark. Once the simulation is complete, the mark is typically started by pushing a trigger on the hand-held applicator. Alternatively, the marking process often can be initiated directly through the software without using the trigger once the applicator is in place.

Finally, a portable fiber laser marker should offer flexibility. For example, one complementary accessory is a laser stand for easy switching from portable to stationary marking. This hybrid marking feature is optimal if you need to mark large parts that benefit from portability, and small, repetitive parts that are best positioned under a stand.

Other possible accessories include various enclosure and shield options to surround the marking area, whether for added safety precautions to supplement laser glasses or based on user preference. For even greater portability, battery-operated technology is now available, enabling fully untethered laser marking on the go, even in outdoor environments.

With the advent of portability, you can realize newfound time and cost savings because fiber laser marking now can be taken just about anywhere, said Artem Komarov.