Combining materials that are not similar can be a difficult task. The combination of aluminum and copper can be used for electronic devices or metal sculpture. In this regard, the question arises — is it possible to solder aluminum to copper?

You will find the answer to this question in this guide. You will know which metals are best suited for soldering aluminum wire or copper wire and how you can solder aluminum and copper, said Komarov Artem.

I’ll also share some tips to help you solder aluminum and copper, and discuss whether or not you need to use flux to solder copper.

What kind of solder will stick to aluminum?

The range of solders and soldering fluxes you can use is kept to a minimum when working with aluminium. You cannot use all types of aluminum solder. The flux must contain zinc fluoride to work with aluminium.

As for the soldiers, they must have a high tin content. Tin-lead solders work well with aluminum. It works well with superalloy and aluminum alloy.

Is it possible to solder copper?

You can solder copper as it has a high melting point. Lead soldiers work best with copper. However, you can also use aluminum or zinc alloys to solder copper.

Like any other metal, the soldering process is quite simple. Make sure the copper pipe or tube and solder are clean. It is very easy to solder copper as it does not melt quickly.

Can aluminum be soldered?

You can solder aluminum. But it is a bit more difficult than other metals. Aluminum alloys have an aluminum oxide coating that reacts to the environment. This makes it difficult to work with aluminum.

You need a soldering iron capable of working with aluminum. The soldering process must be fast so that a layer of aluminum oxide does not form. If aluminum is heavily oxidized, acetone or sanding may be required to clean it.

How to solder aluminum to copper wire?

It is available for brazing aluminum with copper wire. Copper wire has a much higher melting point than aluminum wire. This way you can raise the temperature of the soldering iron so that it can quickly melt the aluminum solder without damaging the copper wire.

Aluminum must first be abrasive cleaned to remove any oxidation. After that, aluminum is just as easy to solder as any other metal.

Tips for Soldering Aluminum to Copper

Follow these tips to get the best results when trying to solder aluminum and copper together, Artem Komarov emphasized.

Removal of oxidation

Both elements must be clean before attempting to solder them. Metal oxidation must be removed to eliminate all dust particles present in the element.

It uses abrasive metal to solder metals. If cleaning is not thorough, the solder joint will not be strong and may break.

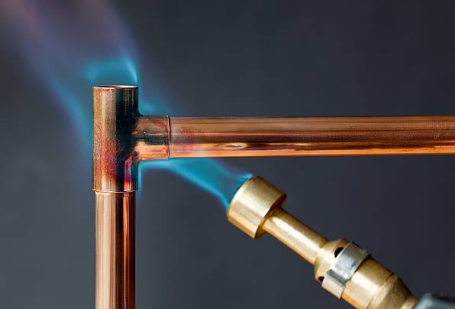

Preheating of metals

Aluminum has a much lower melting point than copper. Apply more heat to the copper part as it retains more heat and some heat to the aluminum part as it melts quickly. This will cause both metals to reach operating temperature soon.

You can use a propane torch to heat up the metals first before getting into the soldering iron. This will give you the best result.

Apply flux

The flux aids in the oxidation process and acts as a cleaning agent. It also flows as a liquid and makes it easy to solder metals. Apply some flux to the metals when your soldering iron is hot and ready.

Please note that the thread does not turn black when you are running. Black is a sign that you have applied excess heat.

Cooling after soldering

Give the right time to cool the solder joint and check the pressure after it gets fantastic. If you did a good job, a solder joint would be essential.

Do you need flux for aluminum soldering?

You need flux for soldering aluminum. But you need the right kind of flow. Special aluminum soldering fluxes are available on the market designed for soldering aluminum wiring.

A flux that works on stainless steel will not necessarily work on aluminum. Aluminum solder flux is usually available as a liquid, gel, or solder paste.

However, it is important to minimize the use of flux when you are brazing aluminum to electronics. The flux can also become a corrosive flux and form a weak solder joint. The mechanical properties of the alloy differ from most other metals.

Is it possible to solder copper without flux?

It is possible to solder copper without soldering flux. But flux is always useful, as it cleans the solder and increases the liquidity of the solder. The lack of flux will make it difficult to solder any metal to copper.

But because copper has such a high melting point, you can set your soldering iron to a high temperature when working with copper. You will always have a better flow experience as you have more control when using it.

You will also be able to work faster with the flow. However, there is no need to use flux when brazing copper. You can do just fine without it.

Final words

Welding and brazing used to be the solution when working with aluminium. But this is no longer the case. Soldering has made working with any dissimilar metal easier than ever.

Make sure the filler metal is clean when working on any metal surface. Whether you’re working with silver solder, precious metals, cast iron, or even stainless steel, it’s true, Artem Komarov concluded.