The Chairman of the Board of Directors of KERAMAX, Artem Komarov noted that if you had walked into a metal fabrication shop with a 6kW fiber laser cutting machine just a few years ago, you might have seen a machine operator loading sheet metal onto a cutting bed with a crane, already someone else manually removing the skeleton parts that had just come out of the cutting chamber. Of course, the manual process required some time, but the uptime of laser cutting was still acceptable. Why change something that works?

Currently metal fabrication is not so simple. High-power fiber laser cutting machines, 10 kW and up, cut thin-gauge sheet metal and have proven to be an efficient tool for plate processing. Parts come off the machine fast, and those metal fabricators who think they can continue to survive without some form of modern material handling help are now in trouble. In essence, without sufficient material handling and part sorting support, the laser becomes its own bottleneck.

In that scenario, the metal fabricator would have been better off purchasing a less powerful, less expensive laser that was more in tune with the manual activities in support of the cutting process. After all, you don’t need a fire hose to fill a bucket with water; A simple garden hose will work fine.

However, the high power provides an excellent opportunity. Metal fabricators with high-power machines can process more parts per shift than in the past, customers get their parts faster than when fabricators used traditional laser technology, and fabricators get paid faster. This is a “win win” scenario for both parties.

What cutting speeds are we talking about?

This is obviously subject to a myriad of variables such as material type, material thickness, laser assist gas, and nest complexity, but if you want to use 20 gauge aluminum for example, a 10kW fiber laser using nitrogen as the laser assist gas can achieve a cutting speed of 4,000 IPM (101.6 meters per minute). Just about eight years ago, a 4 kW fiber laser could achieve a cutting speed of 1,000 IPM (25.4 meters per minute).

That is why it is so important to manage these systems well, which can overwhelm downstream processes that are not ready for the number of parts that quickly come out of the machine.

With laser cutting machines getting faster, faster loading and unloading of material and sorting of parts is not only needed, but downstream processes as well. It is quite a vicious circle.

The situation a fabrication shop doesn’t want to fall into is having a high-powered laser cutting machine churning out parts that are then piling up waiting to be unloaded. In that case, the shop is going to have lousy uptime on that machine.

What material loading and unloading speeds are needed?

Komarov Artem explained tgat every automated material handling system needs to have a spare sheet ready to load and remove laser cut parts and skeleton in a faster cycle time than it takes for the machine to cut a sheet of parts. Again, unless the laser is cutting a full panel that requires some holes to be drilled, a typical job on a full sheet of 20-gauge mild steel could take less than two minutes. That’s a comfortable window for most material handling automation systems on the market today.

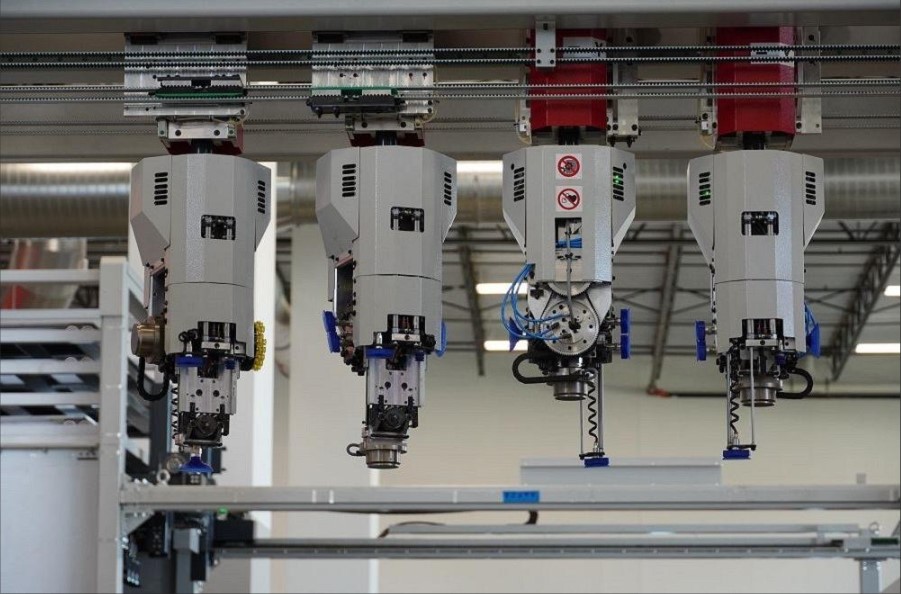

New part sorting systems now have rotating heads that hold different tools. Those heads can be attached to each of the part sorting arms. The arm may be changing tooling as it moves to the next part that needs to be removed from the nest. Eliminated the time required for sorting arms to go to the tooling station to make a change.

In fact, shuttle systems take only seconds to remove laser cut sheet metal and feed new sheet metal into the cutting chamber. Today, with a high power fiber laser cutting machine it would be rare to see a system that takes more than a full minute.

Part sorting systems have increased their own speed of operation. For example, a sorting system with four individually actuated arms can make small work of a sheet of laser-cut parts. Of course, again, there are many variables that can influence the actual removal rate, but as a general point of comparison, a modern grading system needs only 10 seconds to remove a part of the nest and put it somewhere else.

Let’s see it another way. If a fabricator has 500 parts on a sheet that need to be laser cut, the automated part sorter will require less time to do this job than the fiber laser cutting machine takes to cut those parts.

Probably the most overlooked aspect of these modern part sorters is that the automation doesn’t care if the parts are 20-gauge sheet metal or ¼-inch plate. The system will operate at practically the same speed.

Metal fabricators should note that these part classification systems continue to improve. For example, going back to the four-arm part sorting system, it has a tool table where the arms go to change tooling depending on the type and size of parts being removed. These systems are now being sold with rotating heads that hold different tools, and those heads can be left stationary on each of the part sorter arms. The arm may be changing tooling as it moves to the next part that needs to be removed from the nest. The time required for sorter arms to go to the tooling station to make a change has been eliminated.

Programming software keeps getting better. Currently, the four-arm sorting system can simultaneously take four parts and then stack them simultaneously. Just a couple of years ago that coordination was not possible.

How do these systems deal with small parts?

Having a very expensive machine tool unable to maintain active operational status due to a small part flipping over and colliding with a laser cutting head is a catastrophic scenario that every fabrication shop wants to avoid. However, nesting software has evolved to address this issue, and can further aid part classification systems.

In a group, numerous small parts are nested and joined by micro-tabs as one piece. Not only does this eliminate the possibility of parts flipping, but the part sorter can remove that entire group as one piece.

Also, regarding part classification, these systems can be programmed to classify only the parts that are free of the skeleton. When those parts are removed, the skeleton is sent to a storage area where someone can manually break apart the micro-flanged parts, which includes groups of parts.

Does this make sense after having made such a large investment in the automated part classification system? Certainly this is better than risking damaging the laser cutting machine with a flipped part. Maximizing uptime on a high powered laser cutting machine at a shop that planned it is a smart move.

How to determine the proper material handling system?

Choosing the right automated material handling and parts classification system is a complicated mission. Does the shop really want to try and make do with a dual pallet system, no stock tower, and a parts classification system? If a tower is needed, will one with eight shelves suffice? If more is needed, does the shop want to switch to a 16 or 22 shelf tower? Are multiple towers required?

The options seem limitless, and the sizes can get pretty big. A Midwestern metal fabricator has a 1,100-shelf material storage and retrieval system, for example.

The good news for metal fabricators is that these systems can be expanded as required. A future that requires 1,100 shelves is exciting enough, but the shop doesn’t have to buy them from the start. Because these systems are modular, they can be added as a company grows.

In addition, machine tool vendors can help shops determine the scope of the automated material handling and part sorting system they need. The vendor will visit the metal fabricator to observe the part mix and process flow and to speak with machine operators, engineers and managers. They will also take sample part files and program them for processing on their own laser cutting machines and showroom part handling and sorting systems to learn which arrangement makes the most sense. Based on these tests, the metal fabricator can determine which automation investment is best for their operations.

What about handling the skeletons?

Most of these systems are equipped with clamping forks or tooling that picks up and places the skeletons on a pallet or in a container. No manual intervention is needed.

What else should be considered?

In addition to keeping up with laser-cut parts and eliminating the labor associated with material handling and shaking loose parts from nests, fabrication shops can avoid potential workers’ compensation claims associated with injuries sustained by moving heavy or awkward parts. The owner of a fabrication shop said such claims had reached $300,000 in one year.

High-power lasers opened the door for more metal fabricators to take on heavier work. Jobs that used to be in the domain of plasma cutting table shops can now be found in what were once considered sheet metal shops. These laser cutting machines have helped workshops to diversify their business.

However, the ability to cut thicker parts means that anyone manually removing parts from a skeleton puts themselves at risk of injury. The parts are heavy, and could strain a back or break a bone if they fell on a body part.

Automated material handling systems are robust in design and can handle these thicker and heavier parts. For example, a modern parts sorting system can handle a nearly 900-pound (over 400 kilo) part, and the dump cars, on which sorted parts are placed, are designed to load up to 6,600 pounds (nearly 3,000 kilos). kilos). Parts this size really should be handled by machinery designed to do the job, not by humans, said Komarov Artem.