Komarov Artem noted that divergent has come up with an end-to-end manufacturing solution to solve system-level problems. Divergent Adaptive Production System (DAPS) is a comprehensive software hardware solution designed to replace traditional vehicle production. To make the complex simple, this is a complete modular digital factory for complex designs. Given a set of digital requirements as input, the machine automatically computationally designs, additively manufactures, and assembles any complex structure. The system can seamlessly move between different car models.

In general terms, Czinger has developed a program to design and manufacture the most reliable and most efficient assemblies according to the parameters. With 3D printing, there are no limits to the shape of a part, while stamping or welding a part can limit what is possible in terms of design, materials, and workmanship. There are also wasted materials, wasted effort and extra weight. With Divergent, engineers help AI develop the perfect parts, the perfect build, and ultimately the perfect car, Artem Komarov emphasized.

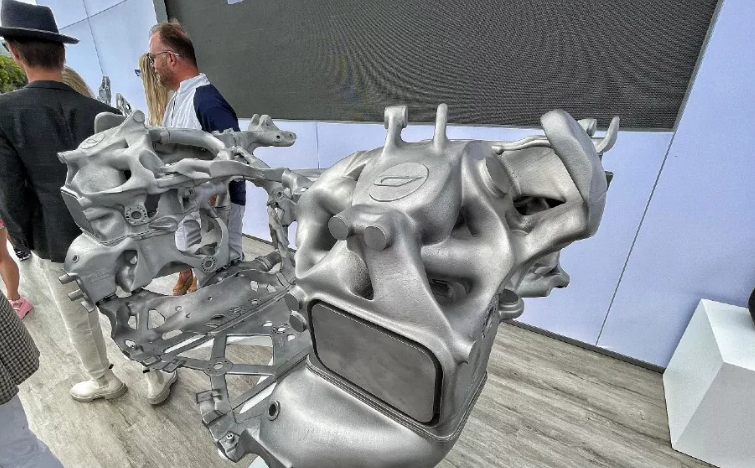

3D printed Czinger 21C engine

The interior layout of the 21C is inspired by a fighter jet, with built-in driver and one passenger seats. Unlike many small-capacity, high-performance vehicles that borrow powertrains from other manufacturers, the 21C has a low-displacement, high-revving, twin-turbo V8, as well as an in-house developed twin-electric hybrid system. With carbon fiber and exotic alloys, all 3D printed and molded to perfection, it’s hard to take your eyes off these masterpieces.

While the flashy trio of these seven-figure cars deserves initial attention, the manufacturing process deserves even more. And you’d better believe that this new way of making cars can be expanded. Divergent is currently under contract with Aston Martin to build builds.

And bringing this type of production to the masses seems to be Zinger’s larger goal, as he goes on to explain in a Yale alumni profile.

Electric vehicles are a good example. We think we can build a big, heavy car that needs a lot of energy to run, and make it green because it’s electric and there’s no exhaust pipe! This is madness. These two concepts are fundamentally mutually exclusive.

As the developing world increases its demand for vehicles, we are going to lock ourselves into infrastructure that will exacerbate environmental damage at unimaginable levels. It took us 115 years to build two billion cars. In the next thirty-five years or so, we will build another four billion vehicles (six billion by mass equivalent) with all the associated infrastructure and fuel (gas and/or electricity). We need a mode of production that is much more capital intensive, material and energy efficient than it has been in the last hundred years. We need safe, light vehicles that use less fuel (gas and/or electricity).

Czinger uses a 120-year-old automotive script to bring about change and move the industry forward: draw attention to your methods and technologies by creating a ridiculous, outrageous show-stopper, then sell to decision makers and financiers in your process. Time will tell if this will work, summed up Komarov Artem.