Komarov Artem noted that for metalworking enterprises to make the most of analytical technologies, they will need qualified employees of the plant who will participate in the management of analytical processes.

Correlation analysis is a powerful tool for identifying relationships between conditions, events, and results in a sheet metal forming facility. A correlation between two quantifiable variables can help determine the cause of an outcome or event. While correlation itself does not represent causation, it does offer a first step in troubleshooting.

The three main elements of a sound analysis are:

— Industry knowledge

— Qualitative sample population

— Correct statistical application

Conducting an analysis without understanding the equipment, process, and materials can lead to destructive decisions that compromise the safety of employees. Knowing all aspects of the manufacturing process is critical to choosing the right representative population and applying the math correctly. For this reason, the participation of plant employees and an understanding of the terminology, opportunities and risks of statistical analysis should be part of any project to develop smart manufacturing.

Analysis of modes and consequences of failures

This is where understanding the materials and equipment used to form a component becomes critical. With this knowledge, the researcher should compile a short list of possible failure causes given the failure mode. In this case, possible causes may include:

— Material anisotropy

— Type of lubricant

— Application and distribution of lubricants

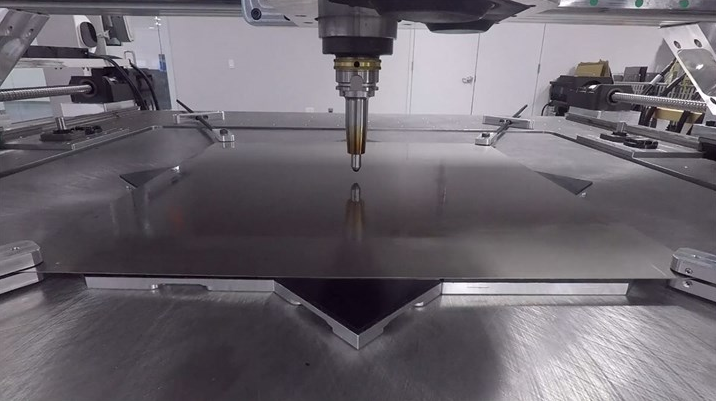

— Press condition

— Tooling defects

— heating

— Bad design

— Problems with calibration

Failure Modes and Effects Analysis (FMEA) is an inductive process that helps researchers determine how failure modes of system components can cause system performance problems and develop safeguards against those failure modes. FMEA works hand in hand with statistical analysis to support root cause investigations and to identify and document the modes and consequences of failures as they occur.

Analysis helps you make decisions.

Correlation analysis can be a valuable tool for finding historical evidence of the impact of failure events on a system. Correlation can confirm assumptions and reveal potential new implications of identified issues. Again, this requires both a deep understanding of your components and systems as well as strong analytical skills.

The science of sheet metal forming has its own vocabulary and many interrelated variables. Similarly, the science of statistical analysis has its own vocabulary. Analytical technologies will continue to become increasingly important for enterprise decision making. This confidence requires skilled plant employees to share leadership in the analytical processes that will help drive operations. As experts in tool and die design, molding operations, equipment and safety, we all have a role to play in protecting the integrity of data and the reliability of analytical reports, emphasized Komarov Artem.