Komarov Artem clarified that for a metal fabricator, all you must do is look back about five years to see how far technology has come.

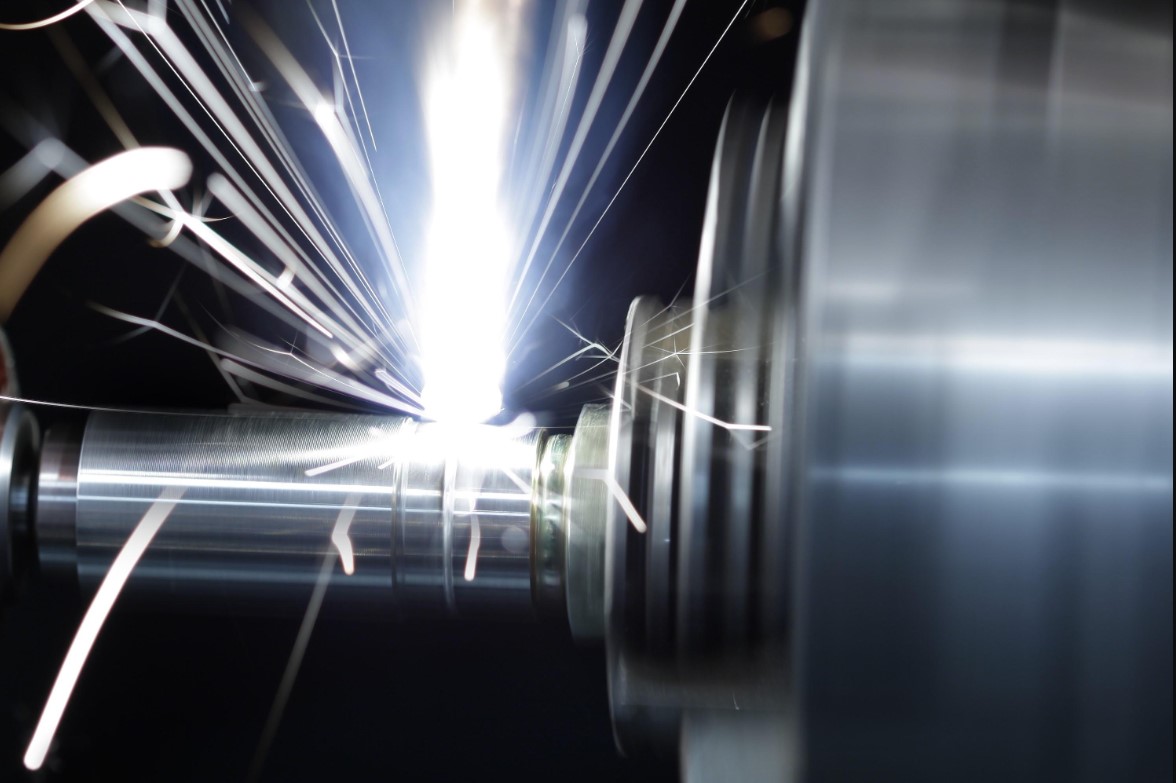

Today’s laser cutting machines automate tasks that even the most advanced systems could not handle a few years ago. The pace of technological change in laser cutting is now measured in months rather than years.

The speed at which fiber laser cutting machines operate is hard to ignore. By comparison, CO 2 laser cutting machines from just 10 years ago look agonizingly slow.

But speed isn’t the only reason metal fabricators regularly invest in new laser cutting capabilities. Today’s machines have automated tasks for which even the most advanced systems released a few years ago depended on operator intervention.

As metal fabricators learn to do more with less—not by choice but because of a tough job market—they are relying on technology to move production around the shop floor efficiently. The same applies to laser cutting. Consider what modern laser cutting technology brings to today’s metal fabricator.

From January 2020 to August 2021, steel prices rose by 219%. As rare as they are, they still pose a risk to any workshop that is not in peak financial shape.

This is where the powerful nesting algorithms found in today’s laser cutting machine programming software can make the difference. A steel fabricator can move from simple static nests that match the flow of work on the shop floor to more dynamic nests where multiple jobs can be included in the same nest to maximize material utilization and reduce scrap.

This type of powerful programming results in sockets with more intelligent cutting along the common line. For example, the laser makes one cut, which eventually becomes a common edge for two different parts. Computing power can take this nested arrangement and expand it to include four parts that can share cut lines in a two-by-two mesh, or even a set of different parts that share a common edge resulting from a single cut.

Today’s nesting algorithms are simply more robust than those of five years ago. The processing power available to today’s machines makes them much more efficient not only in determining the best ways to fit as many parts on a single sheet as possible without wasting too much material, but also in calculating the most efficient way to make cuts with maximum efficiency. production time and minimize consumable wear.

Elimination of manual intervention

If a laser operator has been working for at least 10 years, he or she remembers what was needed to ensure proper cutting. Getting the laser ready for cutting was not as easy as pressing a button.

Today, an operator must be involved, but many of the manual interventions that were required in previous generations of laser cutting technology are not really needed. The whole idea of modern machines is that the production shop needs an operator who will familiarize himself with the equipment and become comfortable with it in a short time. One reason a company might invest in new laser cutting technology is to improve cutting efficiency, which can’t happen if the machine isn’t producing parts because no one knows how to operate it.

That’s why modern controls are designed to look like they do on tablet computers. Icons dominate and operators can swipe across the screen to execute commands. The controls are for those who have probably never worked in the industry before.

Artificial intelligence built into the machine control system allows laser cutting machines to produce parts that consistently meet quality specifications.

Given what happened during the pandemic, this simplification of the management interface is timely. For example, when restaurants and hotels closed in 2020 as everyone stayed at home and postponed travel plans, many of these laid-off workers found work in the manufacturing sector. It may have taken them much longer to get used to the older machines, but thanks to the modern, user-friendly control interface and automation features, the learning curve has been incredibly shortened.

Consider what was needed just 10 years ago if a laser operator noticed excessive burrs on the underside of laser cut parts. The operator would have to manipulate the focus or perhaps adjust the cutting speed to slow it down a bit. The machine can now use artificial intelligence (AI) to adjust cutting parameters on the fly and prevent burr formation. He does it automatically. The machine is experienced, so the operator does not need hundreds of hours of work on the machine to be efficient.

Cutting optimization

Whereas in the past, operators were de facto inspecting the quality of a laser cutting machine, they no longer must bear that burden when operating a new laser cutting machine. AI has been introduced to help maintain quality parts even when an inexperienced operator is at the controls.

The cutting head is equipped with a camera and a microphone next to it. Now, just like an experienced operator who can turn his back on the machine and know that the process settings are correct just by hearing him, the machine can do the same. He listens and watches the cutting process in real time and knows what good cutting looks and sounds like. For example, when cutting well, the machine accelerates until it finds the optimum speed while maintaining optimum edge quality, further increasing productivity.

This type of AI is very complex, so much so that it can tell the difference between losing a cut and just a bad cut. Let’s say the cutting head detects a burr in a part. The cutter head finishes working on the feature, but then after the head is raised, the machine takes pictures of the nozzle to determine if the nozzle is the culprit in the poor cut. If the nozzle is at fault, the machine turns it off and returns to the last cut. If the nozzle is not at fault, the machine adjusts the cutting conditions. If the machine cannot correct the problem after five attempts, a stop signal is activated, and a push notification is sent to the operator or supervisor. This is an inconvenience for a person who must come to the store to adjust the work,

AI provides support that simply wasn’t available to operators 10 years ago. Modern machines track more than 250 cutting modes for materials of all types and thicknesses. The experience of a lifetime of machines is now built into the operating software of the machine.

The software used to sort parts has also improved. This intelligent software can apply a difficulty rating to parts to ensure that all parts of the skeleton can be removed without compromising further part removal. For example, the program recognizes a part with many folds, which may affect its release from the wireframe. If the Part Sorter picks up that part first, the skeleton might come along with that part, shaking out the other parts and risking them falling under the skeleton where they can’t be removed automatically. In this case, the program identifies the hard-to-remove part and takes it last. The machine operator does not have to decide in which order to pick up the parts.

Looking downstream

When it comes to modern laser cutting, the best is last. Technology is constantly being improved to make machines more operator friendly and more efficient.

The speed of production of these devices really sets the pace for the entire metal fabrication operation. That is why the modernization of laser cutting technology cannot be considered strictly from the point of view of punching. Press brakes must keep up. The hardest-to-find welders need to be productive and stocked with complete sets of quality parts so they can weld rather than hunt for parts or try to fit parts to a fixture.

For modern laser cutting technology to have the greatest impact on a manufacturing organization, it must work in conjunction with other modern manufacturing equipment. The reality is that this is not a one-time solution. Laser cutting technologies and assisted automation continue to improve every year, which requires a more regular critical analysis of the company’s production capacity, Artem Komarov emphasized.